Autodesk Fusion: More than CAD, it’s the future of design and manufacturing

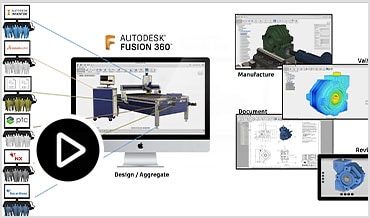

Autodesk Fusion is the first and only integrated cloud CAD, CAM, CAE, and PCB software platform of its kind.

Streamline your product development

Go from design to manufacturing faster with the only all-in-one cloud CAD, CAM, CAE and PCB product development platform, Autodesk Fusion.

Unify your team on one platform

Global manufacturing teams trust Autodesk Fusion to efficiently ideate, create, collaborate and manage their development processes in a single solution with cloud and data at the centre.

Save time and costs with automated workflows

Free up resources to increase capacity with less investment in time and capital with design, electronics and machining automation.

Autodesk Fusion 360 capabilities

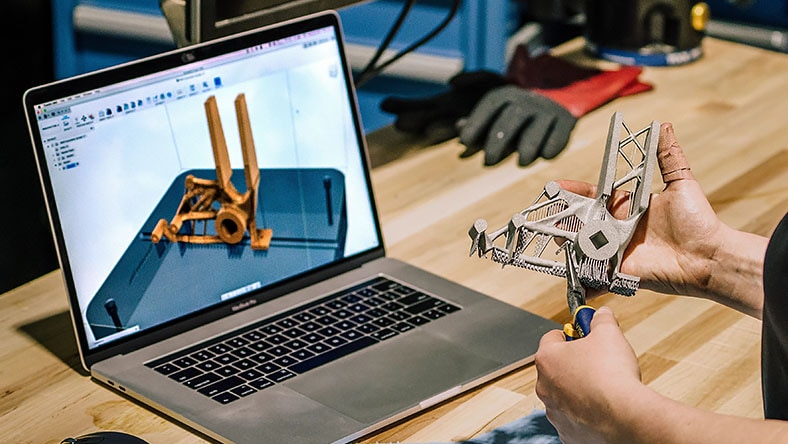

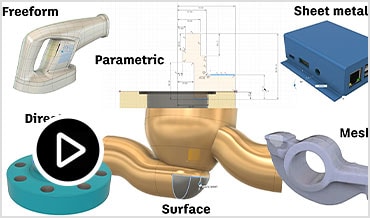

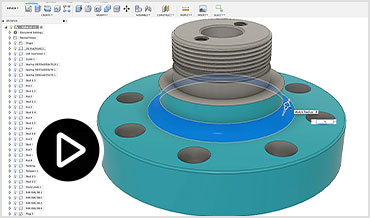

Flexible 3D CAD

Autodesk Fusion enables you to explore many iterations quickly with easy-to-use cloud CAD software.

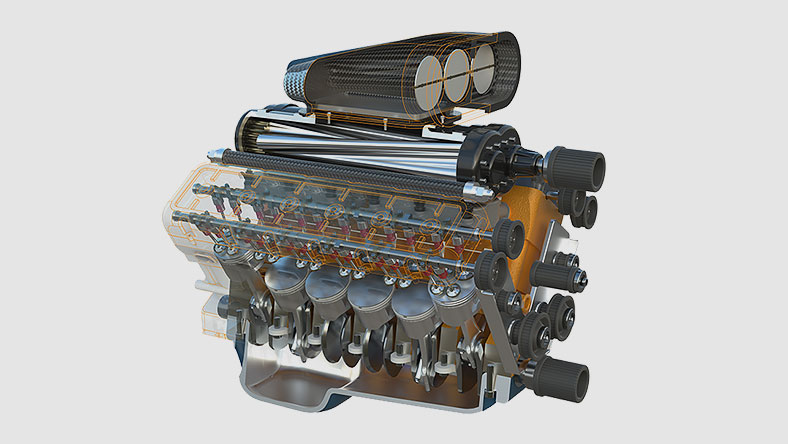

Integrated CAD/CAM

Produce high-quality CNC machined parts and additively manufacture builds using FFF or PBF for metal 3D printing.

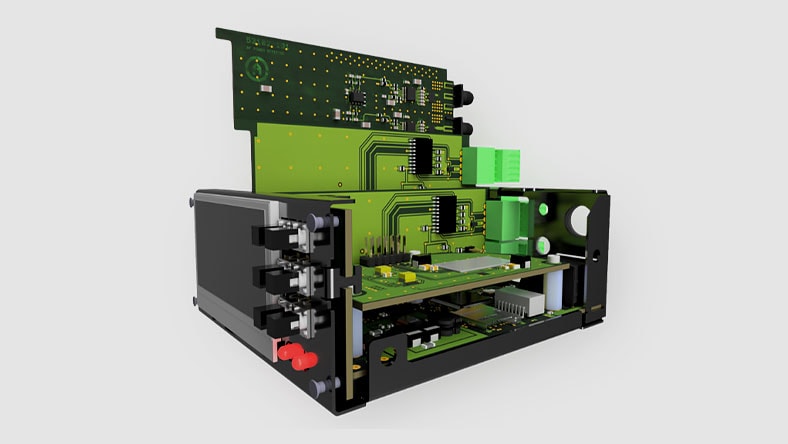

Unified PCB design

Gain all the advantages of a full-featured schematic capture, electronics design and mechanical CAD with Autodesk Fusion.

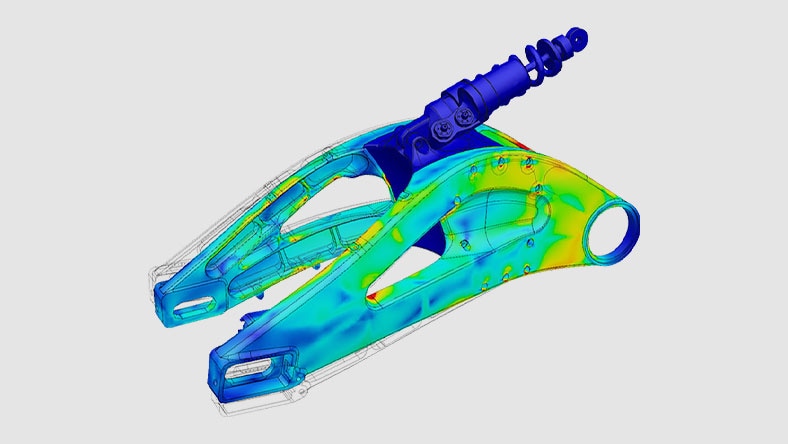

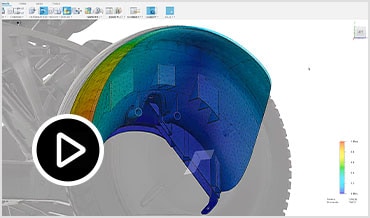

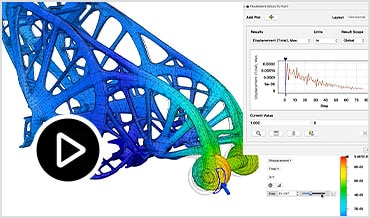

Seamless 3D simulation

Test your designs to ensure that they survive real world conditions. Simulate digitally and reduce prototyping costs.

Explorative generative design tools

Explore many manufacturing-ready outcomes meeting your design specifications through generative design.

Instant-on data management

Use integrated cloud collaboration tools to bring teams together and manage product data.

What you can do with Autodesk Fusion

Flexible 3D modelling and design

Use direct, surface, parametric, mesh or freeform modelling.

Interactive assemblies

Detailed visualisations of complex products with exploded views and animations.

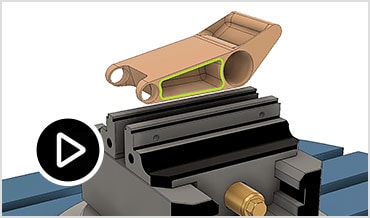

Sheet metal part creation

Design and engineer products to ensure aesthetics, form, fit and function.

Innovative generative design

Explore, design, quote and fabricate faster with automation tools.

Unified electronics and PCB design

Comprehensive electronics and PCB engineering tools.

Push-button SPICE simulation

Easy SPICE (Simulation Program with Integrated Circuit Emphasis) setup.

Unlimited hierarchical schematic capture

Support for 16-layer PCB systems.

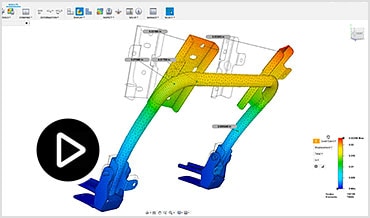

Integrated CAD and CAM

Additive manufacturing, 2 & 3-axis, 3+2, 4 & 5-axis milling and more.

Cloud collaboration and data management

Connect teams, communicate in real time and manage projects with global collaboration.

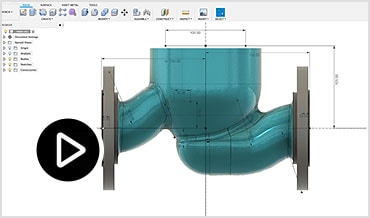

Photo-realistic rendering and documentation

Annotate, dimension and document models with real-life rendering technology.

FEA verification, test and simulation

Topology and shape optimisation with cloud-based machine learning and AI.

Professionals who use Autodesk Fusion

Machine quality parts faster. Reduce cycle times to improve the bottom line.

Smart tools let you connect extended teams in real time.

Process controls to design, simulate and manufacture all in one program.

Unify schematic, PCB, libraries, simulation and mechanical design.

Speed up ideation and connect with engineering teams faster.

Prep students for careers in design, engineering and manufacturing.

Explore features of Autodesk Fusion

3D design and modelling

Sketching

Create and edit sketches with sketch constraints, dimensions and a powerful suite of sketch tools.

Direct modelling

Edit or repair imported geometry from non-native file formats. Make design changes without worrying about time-based features.

Parametric modelling

Create history-based features, including extrude, revolve, loft, sweep etc. that update with design changes.

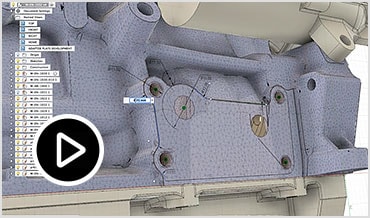

Mesh modelling

Edit and repair imported scans or mesh models, including STL and OBJ files.

Learn more (US Site)

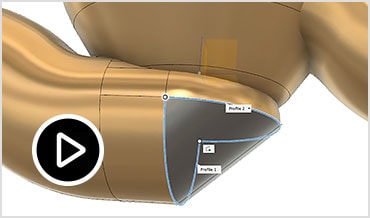

Freeform modelling

Create complex sub-divisional surfaces with T-splines and edit them with intuitive push-pull gestures.

Rendering

Create photo-realistic images of your model, leveraging local or cloud rendering.

PCB design integration

Synchronise bi-directional changes from your electronics designs seamlessly with Autodesk EAGLE interoperability.

Sheet metal

Design sheet metal part components. Document flat patterns using 2D drawings and DXFs. Manufacture your designs with cutting strategies for water jet, laser and plasma machines.

Learn more (US Site)

Manufacturing

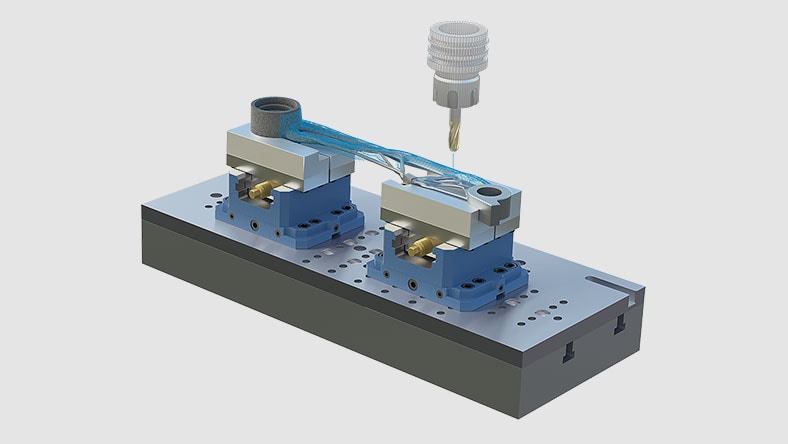

Design to manufacture

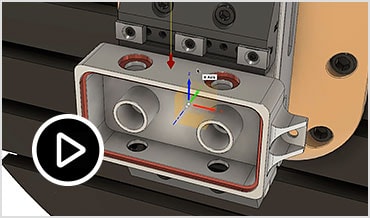

Autodesk Fusion makes it easy to program CNC machines. Use simplified controls for high-efficiency roughing, adaptive clearing and tool orientation. Design for 2D up to 5-axis milling. Simplify probing, turning, mill-turning and profiling operations with a powerful post engine.

2D and 2.5D machining

Set up jobs and create 2D and 2.5D toolpaths to drive CNC routers, mills, water jet cutters, laser cutters and more. Integrated CAD simplifies design revisions, reduces programming times and helps avoid mistakes.

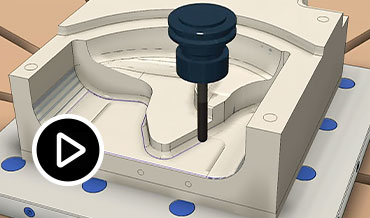

3-axis machining

Access a range of powerful 3-axis machining strategies to rapidly create high-quality NC code to rough and finish your 3D parts. Intuitive workflows make it simple to program individual features or entire parts. Some of these capabilities require a subscription to Autodesk Fusion 360 and the Manufacturing Extension.

Multi-axis positional machining

Unleash your shop’s multi-axis capabilities with 3+1 and 3+2 (positional) machining. Machine parts with fewer setups, using shorter, more rigid cutting tools, for improved part accuracy and faster cycle times. Some of these capabilities require a subscription to Autodesk Fusion 360 and the Manufacturing Extension.

4 and 5-axis simultaneous milling

Use specialised 4- and 5-axis toolpaths to achieve superior surface finish. Additional tool axis controls and automatic collision avoidance help you achieve safe, smooth and predictable machine motion. Access to this functionality requires a subscription to Autodesk Fusion 360 and the Manufacturing Extension.

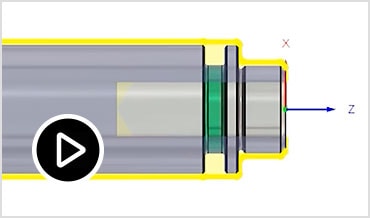

Turning

Programme 2D turned parts using a suite of dedicated turning strategies. Verify your turning toolpaths with stock simulation. Identify errors or collisions with the model, stock, tools and workholding.

Learn more (US Site)

Setup probing and part inspection

Use spindle mounted touch probes to monitor and control your CNC machining. Save time and money by measuring stock material, updating work offsets, monitoring quality, automating part setup, and more. Some of these capabilities require a subscription to Autodesk Fusion 360 and the Manufacturing Extension.

| Autodesk Fusion Manufacturing Extension |

Purchase access to the Machining Extension to unlock advanced CAM capabilities in Autodesk Fusion, including 4- and 5-axis simultaneous machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Electronics

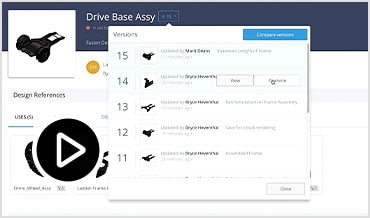

Data management

Administrative tools

Assign permissions and grant rights to stakeholders inside or outside of your organisation with a collection of advanced administrative tools.

User management

Include internal and external stakeholders in your development process. Manage how users interact with data through project administration.

File export

Export a variety of industry-standard file formats making it easier to share and collaborate. File types include STEP, DWG, DXF, OBJ, STL, IGES and more.

Cloud storage

Access your data anywhere and everywhere, on any device. Continue working when not connected to the Internet using offline mode.

AnyCAD

Eliminate the need for translation. Use models and data from any tool directly in your Autodesk Fusion design.

Autodesk Fusion Team Participant

All data management features are included with every Autodesk Fusion subscription or can be purchased separately. Add users to your environment for data management and collaboration purposes only.

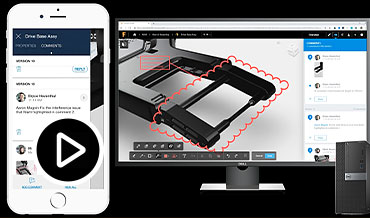

Collaboration

User management

Include internal and external stakeholders in your development process. Manage how users interact with data through project administration.

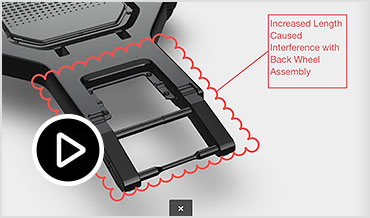

Public/private design sharing

Share links to preview in a web browser, so any third parties can interact with a 3D model, even if they don’t have access to a modelling program.

Autodesk Fusion Team Participant

All data management features are included with every Autodesk Fusion 360 subscription or can be purchased separately. Add users to your environment for data management and collaboration purposes only.

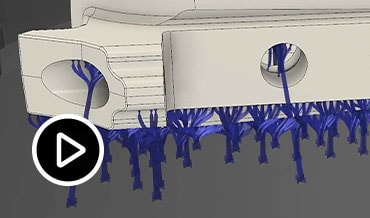

Additive manufacturing

Associative programming

Your toolpaths update with every design change through our fully integrated manufacturing tools, making it quick and easy to machine prototypes.

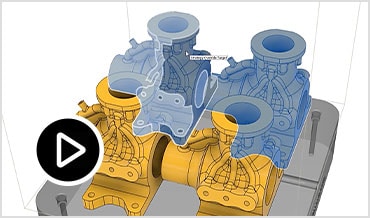

Generative design

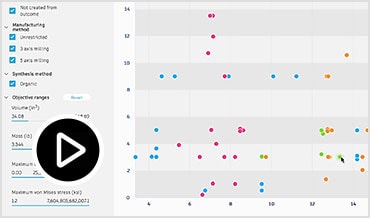

Generative design optimisation

Explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight, improving performance and consolidating parts through generative design.

Manufacturing methods and constraints

Identify your design requirements, constraints, materials and manufacturing options to generate manufacturing-ready designs.

Machine learning and AI

Review cloud-generated design outcomes based on visual similarities, plots and filters powered by machine learning.

Native, editable results

Avoid lengthy, manual import-export processes. Choose your outcome and start editing in your modelling environment immediately.

Cloud solve

Simultaneously solve for various design outcomes, freeing up your time to focus on other tasks.

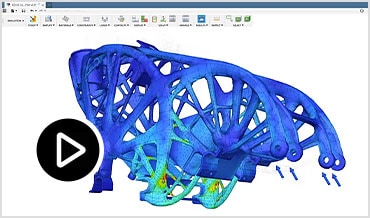

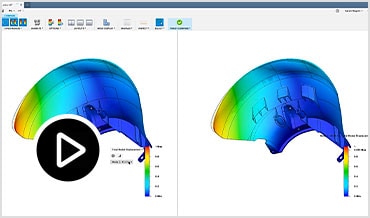

Simulation

Cloud simulation

Using cloud simulation in Autodesk Fusion 360 eliminates the need for expensive hardware. Set up multiple studies to gain insights on finite element analysis through exploration.

Simplify

Cut solve time or explore design changes specific to the simulation workspace.

Compare results

The compare workspace makes it easy to see the benefits of design changes in a single view. Compare up to four different iterations side by side.

Learn more (US Site)

Static stress

Static simulations introduce the benefits of finite element analysis. Determine the effects of static loads on individual parts or assemblies. They are simple to set up and quick to return results.

Modal frequency

Avoid the consequences of unwanted resonance. Use finite element analysis and modal frequency simulations to improve designs. Modal frequency simulation is one of eight different simulations available with Autodesk Fusion 360.

Thermal and thermal stress

Thermal analysis in Autodesk Fusion 360 is crucial. Determine temperature distributions and heat flow of your designs. Use conduction, convection and radiation to improve thermal management with design changes.

Buckling

Predict unexpected failure modes for slender members under compression using simulation.

Non-linear stress

Analyse permanent deformations and non-linear materials of your design.

Event simulation

Test your designs with several impact scenarios. Add time dependencies, inertial effects, velocities, accelerations, damping and mass to your calculations.

Shape optimisation

Remove unnecessary bulk from an existing design. Optimise for light weighting or to maximise stiffness. Using 3D mesh outputs as a guide, you will be able to advance design refinements.

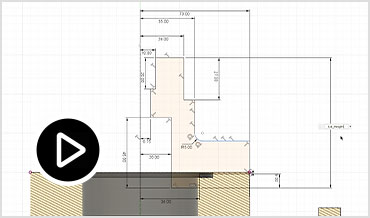

Documentation

2D manufacturing drawings

Turn your 2D designs into detailed parts and assembly drawings. Document manufacturing specifications with drawing templates and stored annotation preferences.

Rendering

Start marketing before a first prototype is even made. To capture design details, drag and drop realistic appearances from an extensive database. Adjust the focal length, exposure and depth of field to create focus.

Animation

Use Autodesk Fusion 360’s animation workspace to create videos that show your design assemblies. Auto explode an assembly or, for more precision, change camera views in manual mode. Export to MP4 to share with stakeholders.

Autodesk Fusion extensions

Innovate faster with extensions

Get even more from your Autodesk Fusion subscription. Access our most advanced design and manufacturing technology with Autodesk Fusion extensions. Flexible cost-effective options help you to access the tools your business needs today.

| Manufacturing Extension |

Unlock advanced CAM capabilities in Autodesk Fusion, including 4- and 5-axis simultaneous machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Simulation Extension

Improve product performance in Autodesk Fusion with the Simulation Extension. Make better products with an assortment of simulation capabilities. Check for structural, thermal, explicit and injection moulding manufacturability. Revise simulation CAD models and studies to compare design changes without exporting.

Design Extension

The Autodesk Fusion Design Extension is a set of advanced 3D design and modeling tools. Enable an automated approach to creating complex product designs. Improve product performance using intelligent feature settings. Apply guidance as you prepare designs for manufacturing.

Signal Integrity Extension

The Autodesk Fusion Signal Integrity Extension, powered by Ansys, is a cost option that unlocks additional PCB/electronics capabilities inside Autodesk Fusion, allowing you to run electromagnetic analysis on critical signals within your PCB.

Manage Extension

Simplify engineering workflows with the Autodesk Fusion Manage Extension. Enable change orders, release management, automated part numbering and bill of materials management.

Reviews

Clear filtersThere are no reviews yet.